Business aviation designers and engineers are beginning to explore how 3D printing can deliver lighter parts, faster iteration cycles and greater customisation while meeting the industry’s rigorous certification and finish quality requirements.

Additive manufacturing (AM) has moved beyond its early role in rapid prototyping. At Hamburg’s ZAL Center of Applied Aeronautical Research, a dedicated team is exploring large-scale and sustainability-focused applications of AM for cabin interiors.

For the LiBio (Lightweight Bionic Aircraft Interior) research project, which was completed in 2023, ZAL

worked with 10 partners to develop a smart cabin table that integrates a screen, speakers, wireless charging and ambient lighting into a 3D-printed base that can be customised for each aircraft. “The result was an elegant and refined cabin table,” says Christopher Tenelsen, an AM expert at ZAL.

ZAL’s partners for LiBio were Bombardier, CRIAQ, F-List, Fraunhofer IFAM, FusiA Group, Inocon Technologie, Joanneum Research, Kansai Helios Austria, Queens University, Solaxis Ingenious Manufacturing, Aerospace & Advanced Composites and IDS.

There was also the RAFINESS (robot-guided AM of integrated, sustainable and electrically conductive

interfaces for cabin sandwich structures) project, completed in 2024. The team built an overhead storage

compartment using only two materials instead of the usual six or seven. “Reinforcement material and

mounting brackets were printed directly onto the base material [honeycomb panels] in a single step,” says Tenelsen. This approach cuts complexity, which could simplify recycling at the end of the bin’s service life, says ZAL, adding that using up to 50% bio-based material also saves fossil resources.

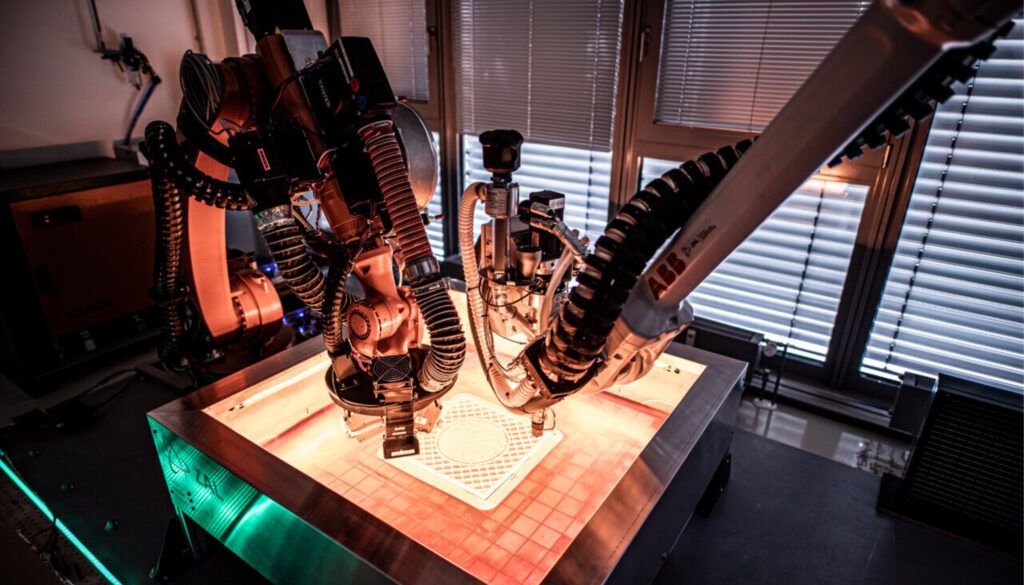

Central to ZAL’s work is the use of industrial robots as automated printing systems.“Thanks to their high degree of freedom, these robots can manufacture complex components over 1m [39.4in] in size, follow

multidimensional toolpaths, and print not only on a flat plane but also in multiple directions,” explains Tenelsen.

Robot-guided manufacturing could enable the semi-automated production of cabin components that traditionally require time-consuming manual steps. Examples include light ornaments or substructures for toilet inserts, shower cubicles or washbasins and rear wall elements.

Tenelsen says robot-guided 3D printing can also produce designer furniture. “AM can provide good support here, especially because the production of such parts requires a lot of manual work by furniture makers, carpenters and other specialists,” he says.

Certification aspects

Tenelsen says AM is promising for business jets because it’s “particularly suitable for smaller fleets or bespoke, one-off designs for VIP cabins”. However, he warns that certification becomes more complex with larger parts: “One of the biggest challenges in AM, especially with plastic parts, is the issue of certification and approval for the cabin sector. There are very high requirements for the materials used and the parts themselves.”

This year ZAL and Lufthansa Technik kicked off the OMCI (Optimized Manufacturing for Cabin Interior) project, funded by the European Regional Development Fund via IFB Hamburg. The research focuses beyond small components such as armrests, covers or cupholders to larger-scale elements.

Lufthansa Technik provided use cases from its VIP Completions department, as well as insights on certification requirements, including the testing and evaluation of samples and components. The company also optimised designs expressly for AM, and explored hybrid manufacturing and joining technologies. “In general, we associate the OMCI project with the hope to gain insights that will enable us to automate the production of large-format cabin components (at least in part) and thus simplify the manufacture of such parts, for example by using fewer components overall, fewer materials, or investing less engineering effort,” says a spokesperson for Lufthansa Technik. “Our VIP Completions business is perfectly suited to this because it mostly involves the production of small quantities with a high degree of component customisation. This is precisely where we see the strengths of AM.”

Decorative pieces

Meanwhile, some VIP aircraft interior designers are working with 3D printing specialists to explore 3D printing applications, with some success. For example, Warja Borges, founder and interior architect at Unique Aircraft, has worked with parts created with both polymer and metal AM. She sees the technology as a breakthrough for decorative and structural elements. She explains that most polymer-based 3D printing materials face flammability certification challenges, apart from two filaments.

Borges says aluminium alloy doesn’t face this problem and has advantages in terms of weight compared with milled parts. But she says achieving a high-level finish for decorative or visible components isn’t that easy. “We did some tests with the standard aluminium alloy for 3D printing, but that’s causing issues in the plating process,” she says. “Anodising would be possible but not at the level of perfection we are looking for in our industry.”

Borges and her project partners are working to overcome this, testing alternative alloys. Despite the complexities, she strongly believes 3D printing holds great promise: “It’s an amazing chance to create a smaller series just for one bespoke aircraft. There are also shapes you literally can’t do with any other production technique.”

The key is for designers to familiarise themselves with the requirements and limitations of the technology. “You need to know what you can do and work with that,” says Borges. “We thought it would be an easy walk to close gaps in the supply chain and get it to the industry, but it isn’t. However, innovation means always walking an extra mile, so we keep going.”

Fellow private aircraft interior designer Natalie Rodríguez also sees opportunities for 3D-printing interior components. While working on a refurbishment at Aeria Luxury Interiors in 2019, she saw first-hand how 3D printing could enable a bespoke seat design. “The design intent behind the seat was to bring a cleaner, more contemporary aesthetic to what was previously a more traditionally styled piece,” says Rodríguez. “While we streamlined the silhouette, we were careful not to lose any sense of refinement or sculptural detail.”

When 3D-printing the armrests, the team was able to include a custom stowage compartment, replacing an obsolete set of controls. The 3D-printed components were wrapped in leather for a cohesive and elevated finish.

“What I value about 3D printing in this context is the precision and repeatability,” says Rodríguez. “We were able to ensure exact replication across multiple units, reducing variability and ensuring a consistent visual and tactile experience throughout the cabin – all while enabling more ambitious design gestures.”

Skills and equipment

Rodríguez believes that access is still the most significant limitation for the use of 3D printing in business jet interior design, since few cabin outfitters have the equipment in-house, nor the staff expert in the discipline. “When these resources are in place, it’s a game-changer – prototyping and replication become faster and more precise,” she says.

Rodríguez typically prints in the polymer Ultem (polyetherimide), which she says passes burn certification requirements as well as being lightweight and more cost-effective than metal. “That said, decorative plating on polymer parts can still be tricky,” she adds. “I’d love to see innovations that make finishing more seamless in this area.”

Rodríguez believes that 3D printing will shift “from a specialist tool to a standard resource” over the next decade. “As cabin outfitters invest in equipment and the people to operate it, and as finishing techniques advance, it will enable us to produce more bespoke, integrated features – from sculptural detailing to functional components – all with the precision and repeatability the technology has delivered for years,” she says.

ZAL’s Tenelsen agrees. “AM clearly has a promising future, as shown by the many research partners from industry and academia collaborating on projects,” he says. “When projects like OMCI demonstrate that these technologies can be applied to larger components and certification pathways are clarified, AM can fully leverage its advantages – allowing even larger parts to make their way into the cabin.”

This feature was written by Marisa Garcia and first published in the September/October 2025 edition of Business Jet Interiors International. For the full feature, click here.